Exhaust tips can reach temperatures of up to 500 to 700 degrees Fahrenheit. Exhaust tips can get extremely hot, with temperatures ranging from 500 to 700 degrees Fahrenheit.

The high temperatures are a result of the exhaust gas exiting the engine and passing through the exhaust system. As the gas flows through the system, heat is generated, and this heat is transferred to the exhaust tips. The intensity of the heat depends on various factors such as the engine’s performance, the exhaust system design, and the duration of engine operation.

It’s important to exercise caution when near the exhaust tips to avoid burns or other accidents.

Factors That Influence Exhaust Tip Heat

Understanding the factors that influence exhaust tip heat is crucial for car enthusiasts and automotive enthusiasts alike. The exhaust tip, located at the rear of the vehicle, plays a vital role in expelling the hot gases produced by the engine. It not only enhances the overall appearance of the car but also serves as an indicator of the engine’s efficiency and power output. In this section, we will delve into the factors that influence exhaust tip heat, focusing on engine efficiency and power output, exhaust system design and materials, and catalytic converters and emissions control devices.

Engine Efficiency and Power Output

The engine’s efficiency and power output significantly impact the amount of heat that is generated and subsequently expelled through the exhaust system. An engine with higher efficiency and power output tends to produce more heat, thereby increasing the temperature of the exhaust gases and, consequently, the exhaust tip.

Factors that contribute to engine efficiency and power output include:

- Engine size and type: Larger engines generally produce more power and generate more heat compared to smaller engines.

- Fuel type: Different fuel types have varying energy densities, affecting the amount of heat produced during combustion.

- Ignition timing and fuel injection: Optimal ignition timing and fuel injection strategies can maximize power output while minimizing fuel consumption, resulting in efficient engine performance.

- Air-to-fuel ratio: The ideal air-to-fuel ratio ensures complete combustion and efficient power generation.

Exhaust System Design and Materials

The design and materials used in the construction of the exhaust system also play a crucial role in determining exhaust tip heat. The exhaust system is responsible for guiding the hot gases away from the engine and safely expelling them into the atmosphere. It consists of various components, including the exhaust manifold, catalytic converter, muffler, and resonator, all of which contribute to heat dispersion.

Key factors to consider in exhaust system design and materials include:

- Exhaust manifold design: The design of the exhaust manifold affects how efficiently the exhaust gases are collected and distributed to the rest of the exhaust system.

- Material composition: The choice of materials, such as stainless steel or ceramic, can impact the level of heat resistance and heat dissipation capabilities of the exhaust system.

- Pipe diameter and length: The size and length of the exhaust pipes influence the backpressure, which affects the overall performance and heat generation of the system.

- Noise reduction measures: Some exhaust systems incorporate noise reduction strategies, such as mufflers and resonators, which can affect the heat dissipation of the system.

Catalytic Converters and Emissions Control Devices

Catalytic converters and other emissions control devices are essential components of modern exhaust systems. They play a vital role in reducing harmful pollutants emitted by the engine, but they also contribute to the amount of heat generated by the exhaust system.

Consider the following factors related to catalytic converters and emissions control devices:

- Catalyst composition and efficiency: The type and efficiency of the catalyst used in the converter can impact the amount of heat generated during the catalytic conversion process.

- Regulatory requirements: Emissions control devices must comply with specific regulatory standards, which may affect their design and heat dissipation capabilities.

- Exhaust gas recirculation (EGR): EGR systems can influence the temperature of the exhaust gases, which, in turn, affects the heat expelled through the exhaust tip.

- Exhaust gas sensors: Advanced exhaust systems incorporate sensors to monitor and control the exhaust gas composition, optimizing the efficiency and heat generation of the system.

By considering these factors, car enthusiasts can gain a deeper understanding of exhaust tip heat and its relationship to engine performance, exhaust system design, and emissions control. It is vital to strike a balance between efficient engine performance and maintaining safe exhaust gas temperatures to ensure longevity and optimal functioning of the vehicle’s components.

The Role Of Fuel Combustion In Exhaust Tip Heat

When it comes to understanding how hot exhaust tips get, one crucial factor to consider is the role of fuel combustion. The combustion process in a vehicle’s engine is responsible for generating power by burning fuel and converting it into mechanical energy. However, this combustion process also produces heat, which is released through the exhaust system, ultimately leading to the rise in temperature of the exhaust tips.

Combustion Process and Temperature

The temperature reached during the combustion process greatly influences the heat generated and subsequently, the temperature of the exhaust tips. As fuel enters the engine’s combustion chamber, it mixes with air and undergoes a chemical reaction ignited by a spark in gasoline engines or compression in diesel engines. This reaction results in the rapid release of energy, generating high-pressure gases and heat as byproducts.

During the combustion process, extremely high temperatures can be reached, often exceeding 2000 degrees Celsius (3632 degrees Fahrenheit) at the hottest point within the engine. These soaring temperatures contribute to the production of a substantial amount of thermal energy, which is carried away by the exhaust gases as they exit the engine.

Impact of Fuel Type and Mixture

The type of fuel used in an engine, as well as its mixing ratio with air, plays a significant role in determining both the efficiency of combustion and the resulting exhaust heat. Different fuel types have varying energy densities, combustion points, and chemical compositions, which affect the amount of heat generated during combustion.

| Fuel Type | Energy Density | Combustion Point |

|---|---|---|

| Gasoline | Approximately 34 – 36 MJ/L | Around 495 – 550 degrees Celsius |

| Diesel | Approximately 36 – 38 MJ/L | Around 250 – 350 degrees Celsius |

The efficiency of combustion also plays a vital role in the heat produced. A richer fuel-to-air mixture will result in more complete combustion, generating higher temperatures and subsequently increasing the heat released through the exhaust system. On the other hand, a leaner mixture may lead to incomplete combustion and lower exhaust temperatures.

Efficiency of Fuel Burn

The efficiency with which fuel burns within the engine cylinders can impact both the power output and the resulting exhaust heat. Factors such as proper fuel atomization, precise fuel injection, and adequate air-fuel mixing contribute to efficient combustion. When combustion is efficient, more of the fuel’s energy is converted into mechanical work, leaving less energy available to be emitted as heat from the exhaust system.

To optimize fuel burn efficiency and reduce excessive heat generation, modern engine designs incorporate various technologies such as direct injection, turbocharging, and advanced ignition systems. These advancements aim to improve fuel efficiency, reduce emissions, and enhance overall performance.

Understanding the crucial role of fuel combustion in the heat generated by exhaust tips provides insight into how different factors, such as fuel type, mixture, and combustion efficiency, can affect the overall temperature of the exhaust system. By optimizing these variables, vehicle manufacturers strive to balance performance, efficiency, and heat management, ensuring safe and reliable operation.

Heat-Induced Component Degradation

Heat-induced component degradation is a common issue that can arise with exhaust systems, particularly in relation to the hot temperatures experienced by exhaust tips. The extreme heat generated by the engine and the exhaust gases passing through the system can have a variety of detrimental effects on the components, leading to potential damage and reduced performance. In this section, we will explore the different ways in which heat can degrade exhaust tips, focusing on three key aspects: corrosion and oxidation, structural weakness and cracking, and discoloration and aesthetic damage.

Corrosion and Oxidation

One of the primary effects of high temperatures on exhaust tips is corrosion and oxidation. As the hot exhaust gases pass through the system, they can react with the metal components, leading to a breakdown of the material over time. This can result in rust formation, pitting, and overall deterioration of the exhaust tip surface. Corrosion and oxidation not only impact the visual appearance of the exhaust tip but can also weaken its structural integrity, making it more prone to cracking and damage.

Structural Weakness and Cracking

The constant exposure to high temperatures can cause structural weakness in exhaust tips. The expansion and contraction of the metal due to heat can lead to stress buildup, eventually causing cracks to form. These cracks can compromise the overall functionality of the exhaust system and may also lead to exhaust leaks, which can affect engine performance and fuel efficiency. It is important to regularly inspect exhaust tips for any signs of structural weakness or cracking to ensure proper functioning of the system.

Discoloration and Aesthetic Damage

Another consequence of extreme heat on exhaust tips is discoloration and aesthetic damage. The intense temperatures can cause the metal surface to change color, often resulting in a blue, purple, or brownish tint. This discoloration not only affects the appearance of the exhaust tip but can also indicate potential heat-related issues. Additionally, the heat can cause the protective coatings or finishes on the exhaust tip to deteriorate, leading to further aesthetic damage and reducing the overall lifespan of the component.

In conclusion, heat-induced component degradation in exhaust tips can manifest in various ways, including corrosion and oxidation, structural weakness and cracking, as well as discoloration and aesthetic damage. Regular maintenance and inspection are crucial to identify and address any issues promptly, ensuring optimal performance and longevity of the exhaust system.

Performance Implications Of High Exhaust Tip Temperatures

High exhaust tip temperatures can have significant performance implications for both the engine and the overall exhaust system. Understanding these implications is crucial for maintaining and improving the efficiency, power, and longevity of your vehicle.

Impact on Engine Efficiency and Power

When it comes to engine performance, exhaust tip temperatures play a vital role. Excessive heat can lead to less efficient combustion, resulting in reduced power output. This is because high temperatures can cause pre-ignition or detonation, which occurs when the air-fuel mixture ignites before the spark plug fires. This phenomenon can reduce engine efficiency, leading to decreased power and overall performance.

Furthermore, sustained high exhaust temperatures can cause thermal stress on key engine components, such as the piston rings or valves. Prolonged exposure to extreme heat can lead to improper sealing or even failure of these critical parts, resulting in decreased engine efficiency and power.

Effects on Exhaust System Components

In addition to affecting engine performance, high exhaust tip temperatures can also have adverse effects on various components of the exhaust system. One such component is the catalytic converter. This essential part of the exhaust system is responsible for reducing harmful emissions. Excessive heat can damage the catalytic converter, reducing its effectiveness in pollutant reduction and potentially leading to the violation of emission regulations.

Another component that can be affected by high exhaust temperatures is the exhaust pipe itself. Extreme heat can cause the pipe to expand and contract rapidly, leading to metal fatigue and potentially resulting in cracks or even complete failure. Moreover, heat can cause the pipes to corrode faster, negatively impacting their lifespan and overall durability.

Potential for Heat-related Failures

In addition to reduced engine efficiency, power output, and potential damage to exhaust system components, high exhaust tip temperatures can also increase the risk of heat-related failures. These failures can include melting or burning of surrounding plastic or rubber components, such as hoses or wiring. Moreover, excessive heat can also contribute to vapor lock, a phenomenon where fuel in the lines vaporizes prematurely due to high temperatures, causing fuel delivery issues and potentially resulting in engine stalling or reduced performance.

It is essential to monitor and manage exhaust tip temperatures to mitigate the risk of these heat-related failures and ensure optimal performance and longevity of the engine and exhaust system.

Diagnostic Methods For Exhaust System Heat

The heat produced by an exhaust system can have a significant impact on the performance and longevity of your vehicle. Monitoring and diagnosing the temperature of exhaust tips is crucial in order to prevent potential issues such as overheating, damage to surrounding components, or reduced engine efficiency. In this section, we will explore two effective diagnostic methods for assessing and understanding the heat generated by exhaust systems.

Infrared Temperature Sensors

Infrared temperature sensors are valuable tools used in the automotive industry to measure the temperature of exhaust tips. These sensors utilize infrared technology to detect thermal radiation emitted by an object, enabling accurate non-contact temperature readings. The sensor is pointed towards the exhaust tip, and the emitted thermal energy is converted into an electrical signal, which is then displayed on a monitor or recorded for further analysis. The benefits of using infrared temperature sensors include:

- Non-contact measurement: Infrared sensors allow temperature measurement without physically touching the exhaust tip, ensuring safety and eliminating the risk of damage or incorrect readings.

- Quick and accurate readings: Infrared sensors provide fast and precise temperature measurements, making it easier to identify any temperature anomalies or potential issues with the exhaust system.

- Wide temperature range: These sensors are designed to measure a broad range of temperatures, allowing automotive technicians to assess both hot and cold spots in the exhaust system accurately.

Thermal Imaging Techniques

Thermal imaging techniques offer an alternative diagnostic method for assessing the heat generated by exhaust systems. This method utilizes thermal cameras to capture and visualize the temperature distribution around the exhaust tip. By analyzing the images produced by these cameras, technicians can identify any irregularities or hotspots that may indicate potential problems. The advantages of using thermal imaging techniques include:

- Detailed visualization: Thermal cameras provide a detailed visual representation of temperature patterns, allowing for a more comprehensive analysis of the exhaust system’s heat distribution.

- Real-time monitoring: Thermal imaging techniques enable real-time monitoring of the temperature changes, making it easier to track any sudden increases or fluctuations that may indicate system malfunctions.

- Identification of underlying issues: By identifying hotspots or unusual temperature gradients, thermal imaging techniques help technicians uncover any underlying problems that may lead to performance issues or potential failures.

Both infrared temperature sensors and thermal imaging techniques provide valuable insights into the heat generated by exhaust systems, allowing for effective diagnosis and preventive maintenance. By employing these diagnostic methods, automotive technicians can ensure optimal performance and longevity of both the exhaust system and the vehicle as a whole.

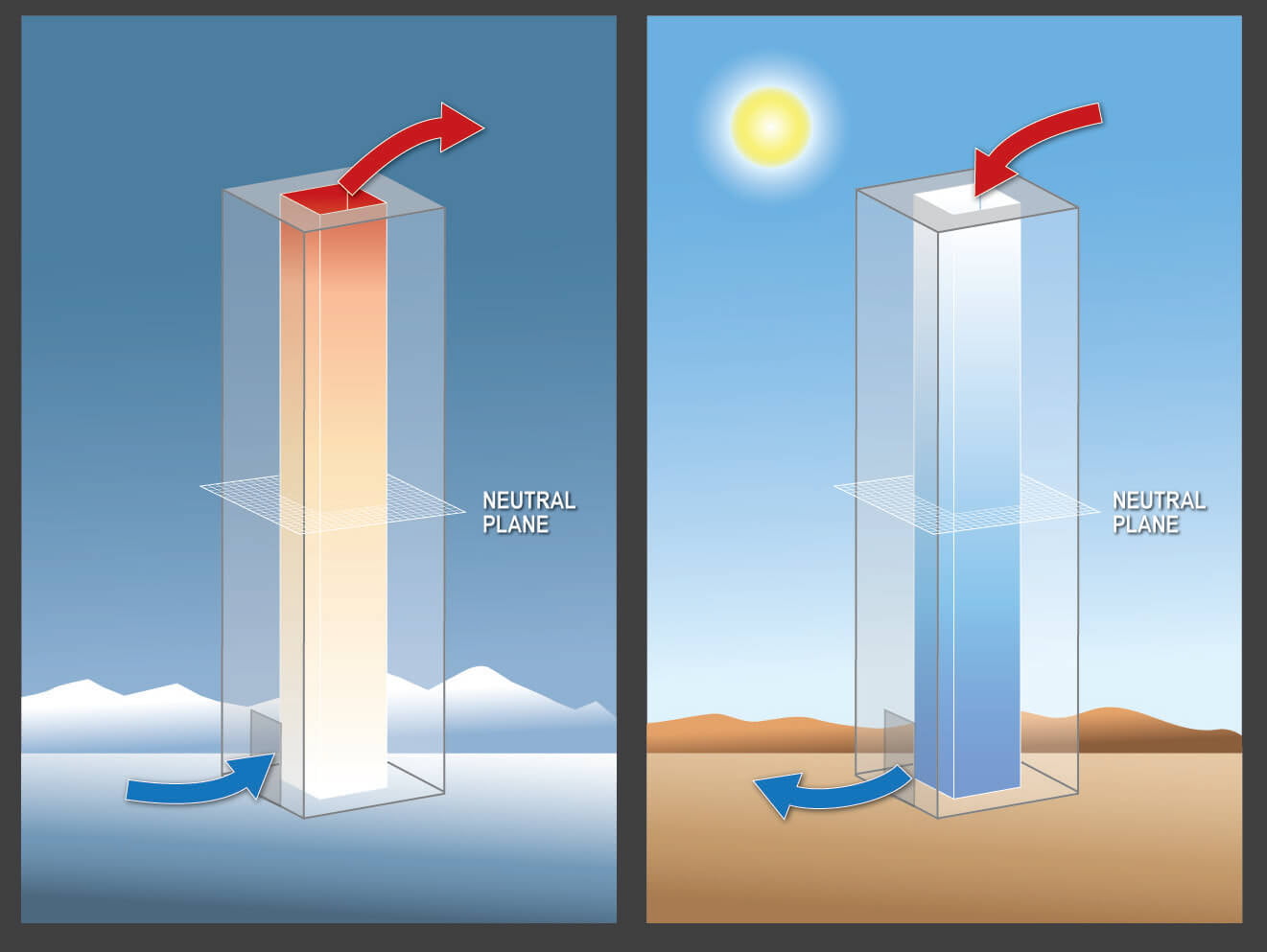

Credit: cppwind.com

Techniques To Reduce Exhaust Tip Temperatures

Reducing exhaust tip temperatures is essential for mitigating potential damage caused by excessive heat and improving overall vehicle performance. Several techniques can be employed to accomplish this, including the use of heat shields and heat wraps, increasing airflow and cooling, and making performance exhaust system modifications. Let’s explore these techniques in more detail.

Heat Shields and Heat Wraps

Using heat shields and heat wraps can be effective in reducing exhaust tip temperatures. Heat shields act as a barrier between the exhaust system and other components, preventing heat transfer to sensitive areas. They are typically made from materials such as aluminum or stainless steel and are designed to withstand high temperatures while reflecting heat away from the exhaust.

Heat wraps, on the other hand, are designed to insulate the exhaust system, keeping the heat contained within the pipes. By reducing heat radiation, heat wraps not only help lower exhaust tip temperatures but also contribute to improved performance by maintaining hotter gases and increasing exhaust gas velocity. However, it’s crucial to note that heat wraps should be used cautiously as excessive heat retention may cause potential damage to the exhaust system.

Increasing Airflow and Cooling

To effectively reduce exhaust tip temperatures, increasing airflow and implementing proper cooling mechanisms are important. By optimizing the airflow around the exhaust system, you can help dissipate heat more efficiently. One way to achieve this is by ensuring proper spacing between the exhaust system and nearby components, allowing for sufficient air circulation.

Additionally, improving cooling systems such as radiator fans, intercoolers, or oil coolers can help decrease exhaust tip temperatures. Efficient cooling systems ensure that the overall heat generated is effectively managed, preventing it from excessively affecting the exhaust system.

Performance Exhaust System Modifications

Making modifications to the performance exhaust system can also have a significant impact on reducing exhaust tip temperatures. Upgrading to a high-performance exhaust system that is specifically designed for improved heat dissipation and airflow can help lower temperatures at the exhaust tips.

Performance exhaust systems may include features such as larger diameter pipes, mandrel-bent tubing for smoother flow, and performance mufflers that enhance exhaust gas evacuation. Additionally, the use of specialized ceramic coatings or thermal wraps on exhaust components can provide further insulation and heat reduction.

By implementing these techniques to reduce exhaust tip temperatures, you can protect your vehicle’s components, enhance overall performance, and ensure a longer lifespan for your exhaust system. Consider consulting with a professional to determine the most appropriate approach for your specific vehicle and requirements.

Frequently Asked Questions For How Hot Do Exhaust Tips Get

Do Muffler Tips Get Hot?

Yes, muffler tips can get hot as they are exposed to exhaust gases. The heat generated by the engine and exhaust system can cause the muffler tips to become hot during operation. It is important to avoid touching the tips to prevent burns or injuries.

What Is The Hottest Part Of The Exhaust System?

The hottest part of the exhaust system is the exhaust manifold. The exhaust manifold collects and directs the hot gases from the engine cylinders to the rest of the exhaust system.

Can Exhaust Tips Melt Bumper?

Yes, exhaust tips can melt a bumper if they come into direct contact for extended periods. Proper clearance between the exhaust system and the bumper is essential to prevent melting and damage. Regular inspection and maintenance can help avoid this issue.

How Hot Does An Engine Average Exhaust Get?

The average temperature of an engine’s exhaust can reach up to 1200 degrees Fahrenheit.

How Hot Do Exhaust Tips Get?

Exhaust tips can reach temperatures as high as 500-700 degrees Fahrenheit, depending on driving conditions and your vehicle’s performance. It’s important to avoid touching hot exhaust tips to prevent burns.

Conclusion

To sum up, understanding how hot exhaust tips get is crucial for car enthusiasts and mechanics alike. By realizing the potential temperature of these components, individuals can prevent unnecessary accidents and ensure the longevity of their vehicles. Regular inspection and maintenance can go a long way in ensuring the safety and efficiency of your car’s exhaust system.

So, don’t overlook the importance of keeping your exhaust tips in check. Stay informed and stay safe!

- How Much Does a Ford 9N Tractor Weigh - May 20, 2024

- How Many of My Exact Car were Made: Uncovering the Rarity - May 20, 2024

- How to Find Out What Someone Drives: Discover the Truth - May 20, 2024