To clean ethanol residue from a carb, use a carburetor cleaner and a cleaning brush or toothbrush. Gently scrub the carburetor to remove any stuck residue.

Then, use a clean cloth to wipe away any excess cleaner. Cleaning ethanol residue from a carburetor is essential for maintaining the smooth functioning of a carbureted engine. Ethanol can leave behind sticky residue, clogging the carburetor jets and affecting the overall performance.

If not cleaned regularly, it can lead to poor engine performance, starting issues, and even damage to the carburetor components. To ensure optimal performance, it is crucial to remove ethanol residue from the carb thoroughly. We will provide a step-by-step guide on how to effectively clean ethanol residue from the carburetor, allowing your engine to run smoothly and efficiently.

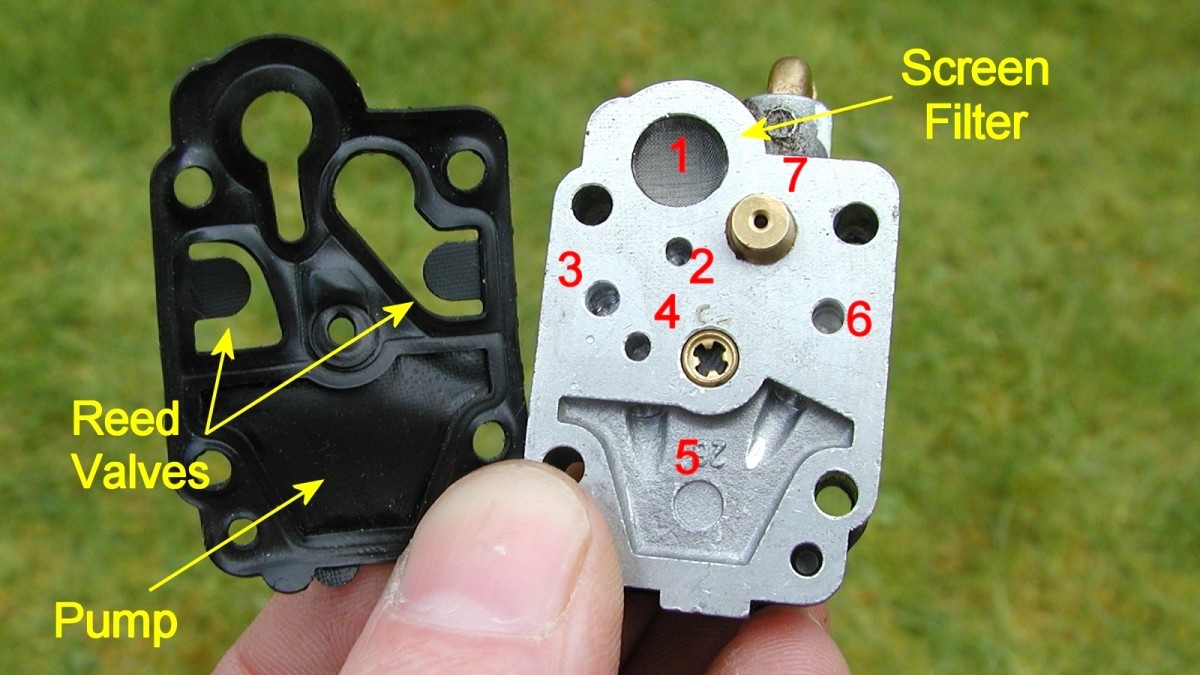

Credit: dengarden.com

Understanding Ethanol Residue Buildup

Ethanol residue buildup in carburetors can be a common issue for many vehicle owners, especially those who use gasoline with a high ethanol content. This buildup can have various negative impacts on the performance of the carburetor, leading to decreased fuel efficiency and overall engine performance.

In this section, we will explore what ethanol residue is, why it accumulates in carburetors, and the impact it can have on your vehicle’s carburetor.

What Is Ethanol Residue And Why Does It Accumulate In Carburetors?

- Ethanol residue refers to the sticky, gummy substance that is left behind after the evaporation of fuel containing ethanol. It is a byproduct of the ethanol and other additives present in gasoline.

- Ethanol, which is commonly derived from corn, is added to gasoline as an oxygenate to enhance combustion efficiency and reduce emissions.

- The accumulation of ethanol residue in carburetors is primarily due to the tendency of ethanol to attract and absorb water from the environment. This absorbed water combines with the ethanol and other fuel components to form deposits over time.

The Impact Of Ethanol Residue On The Performance Of Your Carburetor.

- Reduced fuel flow: As ethanol residue builds up in the tiny passages of the carburetor, it can restrict the flow of fuel into the combustion chamber. This can result in poor engine performance and decreased fuel efficiency.

- Clogged jets and idle circuits: Ethanol residue tends to gather around the jets and idle circuits of the carburetor, obstructing the smooth flow of fuel. This can lead to rough idling, stalling, and difficulty starting the engine.

- Poor atomization: The presence of ethanol residue can interfere with the ability of the carburetor to properly atomize the fuel, resulting in incomplete combustion and reduced power output.

- Corrosion: Ethanol itself has corrosive properties, and when combined with moisture, it can lead to the corrosion of metal components in the carburetor. This corrosion can further hinder the carburetor’s performance and potentially cause damage over time.

Regular maintenance and cleaning of carburetors are essential to mitigate the negative effects of ethanol residue buildup. In the next section, we will discuss effective methods to clean ethanol residue from carburetors and ensure optimal performance of your vehicle’s engine.

Essential Tools And Supplies For Cleaning

When it comes to cleaning ethanol residue from your carb, having the right tools and supplies is crucial for an effective cleaning process. Here are the key items you’ll need and how they contribute to a thorough carb cleaning:

- Safety goggles: Protecting your eyes from any potential splashes or debris is essential. Safety goggles will keep your eyes safe while you work on cleaning your carb.

- Latex gloves: Wearing latex gloves will not only protect your hands from any harsh chemicals but also prevent any contamination from oils or dirt on your hands, ensuring a clean and effective carb cleaning process.

- Carb cleaner spray: A high-quality carb cleaner spray is a must-have for removing ethanol residue and other contaminants from your carb components. Look for a cleaner specifically designed for carburetors to ensure the best results.

- Soft-bristle brush: Using a soft-bristle brush will help you gently scrub away any stubborn residue. This tool is especially useful for reaching tight spots and crevices that may be difficult to clean by hand.

- Compressed air can: Having a compressed air can allows you to effectively blow away any loose debris and particles that may be stuck in your carburetor. This tool helps ensure a thorough cleaning and prevents any clogging or buildup.

- Microfiber cloth: A microfiber cloth is ideal for wiping down the carburetor components and ensuring a clean, lint-free finish. It is soft, absorbent, and won’t leave any scratches on delicate surfaces.

- Carburetor rebuild kit (optional): If your carburetor is in need of a more extensive cleaning or repair, consider getting a carburetor rebuild kit. This kit includes various gaskets, seals, and other small parts that may need to be replaced during the cleaning process.

- Cleaning bucket: Having a designated cleaning bucket will help keep all your tools and supplies organized in one place. This will make your carb cleaning process more efficient and convenient.

Remember, using the right tools and supplies is essential for an effective carb cleaning process. With these items at hand, you’ll be well-prepared to tackle any ethanol residue on your carburetor.

Step-By-Step Cleaning Process

Preparing Your Carburetor For Cleaning:

Before you begin the cleaning process, it is important to prepare your carburetor properly. Follow these steps to ensure you have everything in order:

- Gather the necessary tools: You will need a carburetor cleaning kit, a can of carburetor cleaner, a small container for soaking parts, a soft brush, and a clean towel.

- Disconnect the carburetor: Remove the carburetor from the engine to make cleaning easier and prevent any damage to other components.

- Take safety precautions: Wear protective gloves and goggles to shield yourself from any chemicals or debris that may be released during the cleaning process.

- Find a suitable workspace: Work in a well-ventilated area with plenty of space to lay out the carburetor components and perform the necessary cleaning steps.

Disassembling The Carburetor For A Thorough Clean:

To clean ethanol residue effectively, you need to disassemble the carburetor completely. Follow these steps to ensure a thorough clean:

- Remove the fuel lines and filter: Disconnect the fuel lines and remove the filter to access the carburetor.

- Take note of the carburetor’s layout: Before disassembling, take a few pictures or make a diagram to help you remember how the parts fit together.

- Disassemble the carburetor: Carefully separate each component of the carburetor, such as the float bowl, jets, and needle valve, ensuring you keep track of where each part belongs.

- Use caution with small parts: Some carburetor components, such as small springs and o-rings, are easily misplaced or damaged. Handle them with care and keep them in a safe place.

Removing And Inspecting Individual Components:

Once the carburetor is disassembled, it’s time to remove and inspect each component. Here’s what you need to do:

- Inspect for damage and wear: Thoroughly examine each part for any signs of damage, corrosion or wear and tear. If needed, replace any damaged components to ensure optimal performance.

- Clean with carburetor cleaner: Use carburetor cleaner and a soft brush to remove any built-up residue, paying close attention to tiny passages and ports within the carburetor. Ensure you clean both the exterior and interior surfaces of each component.

Using Specific Cleaning Agents To Dissolve Ethanol Residue:

Ethanol residue can be stubborn, but there are specialized cleaning agents designed to dissolve it effectively. Here’s how to use them:

- Soak components in a cleaning solution: Place the carburetor parts in a container filled with a carburetor cleaning solution, making sure they are fully submerged. Refer to the product instructions for the recommended soaking time.

- Allow the solution to work: Let the cleaning solution dissolve the ethanol residue by allowing the parts to soak for the specified time. This will help to break down any stubborn deposits.

- Rinse with water: After soaking, rinse each component with water to ensure the cleaning solution and any loosened residue are completely removed. Use a soft brush to gently scrub away any remaining debris.

Cleaning Each Component Meticulously:

To ensure a properly cleaned carburetor, it’s important to clean each component meticulously. Follow these steps:

- Use compressed air: After rinsing, use compressed air to blow out any water remaining in the carburetor and to clear any debris from tiny passages.

- Inspect once more: Take a final look at each part to ensure they are clean and free from any leftover residue or debris. Any remaining dirt or buildup can hinder the carburetor’s performance.

Reassembling The Carburetor Correctly:

Now that you have cleaned each component, it’s time to reassemble the carburetor. Follow these steps to ensure proper reassembly:

- Refer to your reference photos or diagram: Use the pictures or diagram you took earlier to guide you as you put the carburetor back together.

- Place each component in its correct position: Carefully reattach each part, ensuring they are placed correctly and securely. Pay close attention to gaskets and o-rings, making sure they are seated properly.

- Tighten screws and fasteners: As you reassemble, make sure to tighten all screws and fasteners to the manufacturer’s specifications. Avoid overtightening, as it can lead to damage or leaks.

Final Steps To Ensure A Properly Cleaned Carburetor:

To wrap up the cleaning process and ensure your carburetor is ready for use, follow these final steps:

- Replace any worn-out parts: If during the cleaning process you noticed any damaged or worn-out components, now is the time to replace them to ensure optimal performance.

- Perform a functional test: Once the carburetor is reassembled, reinstall it in your engine and perform a functional test. Make any necessary adjustments to ensure proper fuel delivery and overall performance.

- Dispose of cleaning agents properly: Follow the manufacturer’s instructions for disposing of any leftover cleaning agents or solutions in an environmentally responsible manner.

By following these step-by-step cleaning processes, you can effectively remove ethanol residue from your carburetor and ensure smooth engine performance. Remember, regular maintenance and cleaning are essential to keep your carburetor operating at its best.

Tips For Preventing Ethanol Residue Buildup

The Importance Of Using Fuel Stabilizers

- Fuel stabilizers are essential to prevent ethanol residue buildup in carburetors.

- By adding a fuel stabilizer to your gasoline, you can prolong its shelf life and prevent the formation of harmful deposits.

- Fuel stabilizers work by inhibiting the oxidation of fuel, which in turn prevents the formation of ethanol residue.

- Additionally, fuel stabilizers help to maintain the correct fuel-to-air ratio, ensuring optimal engine performance.

- Using a fuel stabilizer is especially crucial for equipment that is not regularly used, such as lawnmowers, boats, or motorcycles.

- Make sure to choose a fuel stabilizer that is specifically designed for ethanol-blended fuels.

- Follow the instructions provided by the manufacturer for the correct dosage and mixing ratio.

Regular Maintenance Practices To Minimize Ethanol Residue Buildup

- Regular maintenance is key to preventing ethanol residue buildup in carburetors and maintaining peak engine performance.

- Regularly inspect and clean your carburetor to remove any existing ethanol residue.

- Use a carburetor cleaner or a cleaning solution specifically formulated for carburetors.

- Remove the carburetor from the engine and disassemble it carefully to ensure a thorough cleaning.

- Soak the carburetor parts in the cleaning solution, scrubbing them gently with a brush to remove any residue.

- Rinse the parts thoroughly with clean water and let them dry completely before reassembling the carburetor.

- Consider adding a fuel filter to your carburetor setup to further prevent debris and residue from entering the system.

- Regularly replace the fuel filter to ensure optimal fuel flow and minimize the risk of ethanol residue buildup.

- Lastly, consult your equipment’s manual for specific maintenance recommendations and schedules.

Choosing The Right Fuel For Your Carburetor To Avoid Ethanol-Related Issues

- Selecting the appropriate fuel for your carburetor is crucial in preventing ethanol-related issues and residue buildup.

- Opt for fuels with lower ethanol content, such as e10 (containing 10% ethanol) or even e0 (ethanol-free) fuels, if available.

- Check with your local gas station or fuel supplier to determine the ethanol content in the fuel options they offer.

- High-performance engines may require ethanol-free fuel or fuels with minimal ethanol content to ensure optimal combustion and performance.

- In cases where ethanol-blended fuels are the only option, consider adding a fuel stabilizer to mitigate the negative effects of ethanol.

- It is also important to store your fuel properly. Use approved fuel containers and keep them tightly sealed to prevent moisture absorption, which can contribute to ethanol-related issues.

- Avoid storing fuel for extended periods whenever possible. Instead, purchase fuel in smaller quantities to ensure freshness.

- Lastly, regularly inspect your fuel lines and fittings for any signs of leaks or deterioration. Any leaks can increase the risk of fuel contamination and ethanol residue buildup.

Remember, by prioritizing fuel stabilizers, practicing regular maintenance, and choosing the right fuel, you can effectively prevent ethanol residue buildup in your carburetor and keep your engine running smoothly.

Frequently Asked Questions On How To Clean Ethanol Residue From Carb

How Does Ethanol Residue Form In Carburetors?

Ethanol residue forms in carburetors when ethanol-blended fuels evaporate, leaving behind a sticky residue that clogs the carburetor’s passages.

What Problems Can Ethanol Residue Cause In Carburetors?

Ethanol residue can cause problems such as clogged jets, restricted fuel flow, poor engine performance, difficulty starting, and stalling.

How Often Should I Clean Ethanol Residue From My Carburetor?

It is recommended to clean ethanol residue from carburetors every 50–100 hours of engine use or at least once a season.

What Are Some Signs That My Carburetor Has Ethanol Residue?

Signs that your carburetor may have ethanol residue include hard starting, rough idle, hesitation, bogging down, and decreased fuel efficiency.

How Can I Effectively Clean Ethanol Residue From My Carburetor?

To clean ethanol residue from your carburetor, remove it from the engine, disassemble it, soak the parts in carburetor cleaner, and use a brush to scrub away any remaining residue.

Conclusion

After following the steps outlined in this blog post, you should now have a good understanding of how to clean ethanol residue from your carburetor. By using the right tools, such as carburetor cleaner and a small brush, you can effectively remove any build-up and restore your carburetor’s performance.

It is important to be thorough in your cleaning process, ensuring that all parts are properly cleaned and dried before reassembling. Regular maintenance and cleaning of your carburetor will help prevent ethanol residue build-up, extending the life of your engine and improving its overall performance.

Remember to take necessary safety precautions, such as wearing gloves and working in a well-ventilated area. By following these guidelines, your carburetor will be running smoothly and efficiently for years to come.

- How Much Does a Ford 9N Tractor Weigh - May 20, 2024

- How Many of My Exact Car were Made: Uncovering the Rarity - May 20, 2024

- How to Find Out What Someone Drives: Discover the Truth - May 20, 2024