To test the ignition module on a hei distributor, follow these steps. Start by disconnecting the distributor cap and spark plug wires.

Then, use a multimeter to measure the resistance between the module’s terminals. If the reading is outside the specified range, the ignition module may be faulty and should be replaced. Additionally, check for any signs of physical damage or corrosion on the module.

By performing these tests, you can accurately diagnose and address any issues with the ignition module on a hei distributor.

Credit: www.chevyhardcore.com

Understanding The Ignition Module And Its Importance

The ignition module is a crucial component of the high energy ignition (hei) distributor system. A hei distributor is a type of ignition system used in many modern vehicles to create the spark needed to ignite the fuel-air mixture in the engine cylinders.

The ignition module plays a vital role in ensuring that this spark is generated at the right time and in the right amounts, optimizing engine performance. Let’s dive deeper into what the ignition module is and why it is so important.

What Is The Ignition Module And Its Role In The Hei Distributor?

The ignition module is an electronic component located inside the distributor housing. Its main role is to control the ignition coil, dictating when and for how long the coil generates the high voltage needed for spark creation. Here are the key points to understand about the ignition module and its role:

- The ignition module acts as a switch that turns the ignition coil on and off, controlling the timing and duration of the spark.

- It receives signals from various engine sensors, including the crankshaft position sensor, to determine the precise moment to fire the spark plugs.

- By accurately timing the spark, the ignition module ensures optimum engine performance, fuel efficiency, and emissions control.

- It also provides a crucial safeguard by protecting the ignition coil from overheating and potential damage.

- The ignition module is an integral part of the hei distributor system, which combines the ignition coil and other ignition components into a single unit, simplifying the design and improving reliability.

Understanding the vital role the ignition module plays in the hei distributor system is essential for troubleshooting ignition issues and maintaining optimal engine performance.

The Importance Of The Ignition Module For Engine Performance

Now that we know what the ignition module is and how it functions, let’s explore its importance in relation to engine performance. Here are the key points to consider:

- The ignition module ensures precise timing of the spark, allowing for efficient combustion and optimal power delivery.

- A malfunctioning or failing ignition module can lead to misfires, rough idle, poor acceleration, and reduced fuel economy.

- By controlling the ignition coil, the ignition module ensures reliable spark generation, reducing the chances of a no-start condition.

- It plays a significant role in emission control, helping the engine to meet stringent environmental regulations.

- Regular maintenance and periodic testing of the ignition module can help identify potential issues and prevent costly repairs.

The ignition module is a crucial component in the hei distributor system, responsible for controlling the ignition coil and optimizing engine performance. Understanding its function and importance is key to troubleshooting ignition problems and maintaining a smoothly running engine.

Signs Of A Faulty Ignition Module

A properly functioning ignition module is crucial for the smooth operation of a vehicle’s engine. However, like any other component, ignition modules can develop faults over time. It is important to be able to recognize the signs of a faulty ignition module in order to diagnose and fix the issue promptly.

Here, we outline some common symptoms indicating a faulty ignition module:

- Intermittent or complete loss of power: One of the most common indicators of a faulty ignition module is the loss of power to the engine. The engine may misfire, hesitate, or experience a loss of power intermittently or consistently. This lack of power can be unsettling and make it difficult to drive the vehicle smoothly.

- Engine stalling: Another sign of a faulty ignition module is the engine stalling during operation. If the ignition module is not working properly, it may cause the engine to suddenly shut off while driving, leading to potential safety hazards and inconveniences.

- Difficulty starting the engine: A faulty ignition module can also make it difficult to start the engine. You may experience prolonged cranking or multiple attempts needed to start the engine successfully. This can be frustrating and time-consuming, especially when you need to quickly get on the road.

- Engine backfiring: Backfiring occurs when the fuel-air mixture in the engine’s cylinders ignites outside the normal combustion chambers. A faulty ignition module can lead to inconsistent spark timing, resulting in engine backfires. This can cause loud noises and potentially damage the engine if not addressed promptly.

- Engine hesitation or rough idling: If you notice your engine hesitating or idling roughly, it could be a sign of a faulty ignition module. Irregular spark timing or disrupted fuel delivery caused by a malfunctioning module can result in these symptoms.

- Increased fuel consumption: A malfunctioning ignition module can cause an inefficient combustion process, leading to increased fuel consumption. If you find that your vehicle is burning more fuel than usual, it might be worth investigating the health of your ignition module.

- Engine overheating: In some cases, a faulty ignition module can contribute to engine overheating. The malfunctioning module may cause incorrect spark timing, which can lead to increased engine temperature. Ignoring this issue can result in irreversible damage to the engine and should be addressed as soon as possible.

- Illuminated check engine light: When an ignition module is failing, it can trigger the vehicle’s onboard diagnostics system to illuminate the check engine light. If you notice the check engine light is on, it is essential to have the vehicle diagnostically scanned to identify any underlying issues, including a faulty ignition module.

Being able to recognize these signs of a faulty ignition module can help you address the issue promptly. If you experience any of these symptoms, it is recommended to consult a qualified mechanic or perform the necessary diagnostic tests to determine whether the ignition module requires repair or replacement.

Remember, a well-functioning ignition module is essential for the optimal performance and reliability of your vehicle’s engine.

Step-By-Step Guide To Testing Ignition Module On A Hei Distributor

If you’re experiencing engine troubles and suspect that the ignition module on your hei distributor may be the culprit, it’s important to test it properly to confirm the issue. By following a step-by-step guide, you can diagnose the problem accurately and take the necessary measures to fix it.

Here’s how to test an ignition module on a hei distributor:

Gathering The Necessary Tools And Equipment

Before you begin the testing process, it’s essential to gather the tools and equipment you’ll need. Here’s a list of items required for this procedure:

- Multimeter: A digital or analog multimeter is essential for measuring electrical readings accurately.

- Screwdrivers: You’ll need both flathead and phillips head screwdrivers to disconnect wires and access the ignition module.

- Safety goggles and gloves: Ensuring your safety is crucial when working with electrical components.

- Pen and paper: Keeping a record of your test results and readings will help you troubleshoot and diagnose potential issues effectively.

Safely Disconnecting The Battery And Accessing The Ignition Module

To ensure your safety and prevent any damage to the components, follow these steps to disconnect the battery and access the ignition module:

- Put on your safety goggles and gloves for protection.

- Locate the battery in your vehicle and disconnect the negative terminal to cut off power.

- Identify the position of the hei distributor and remove any necessary components that obstruct accessing the ignition module.

- Use the appropriate screwdrivers to remove the screws or bolts securing the distributor cap.

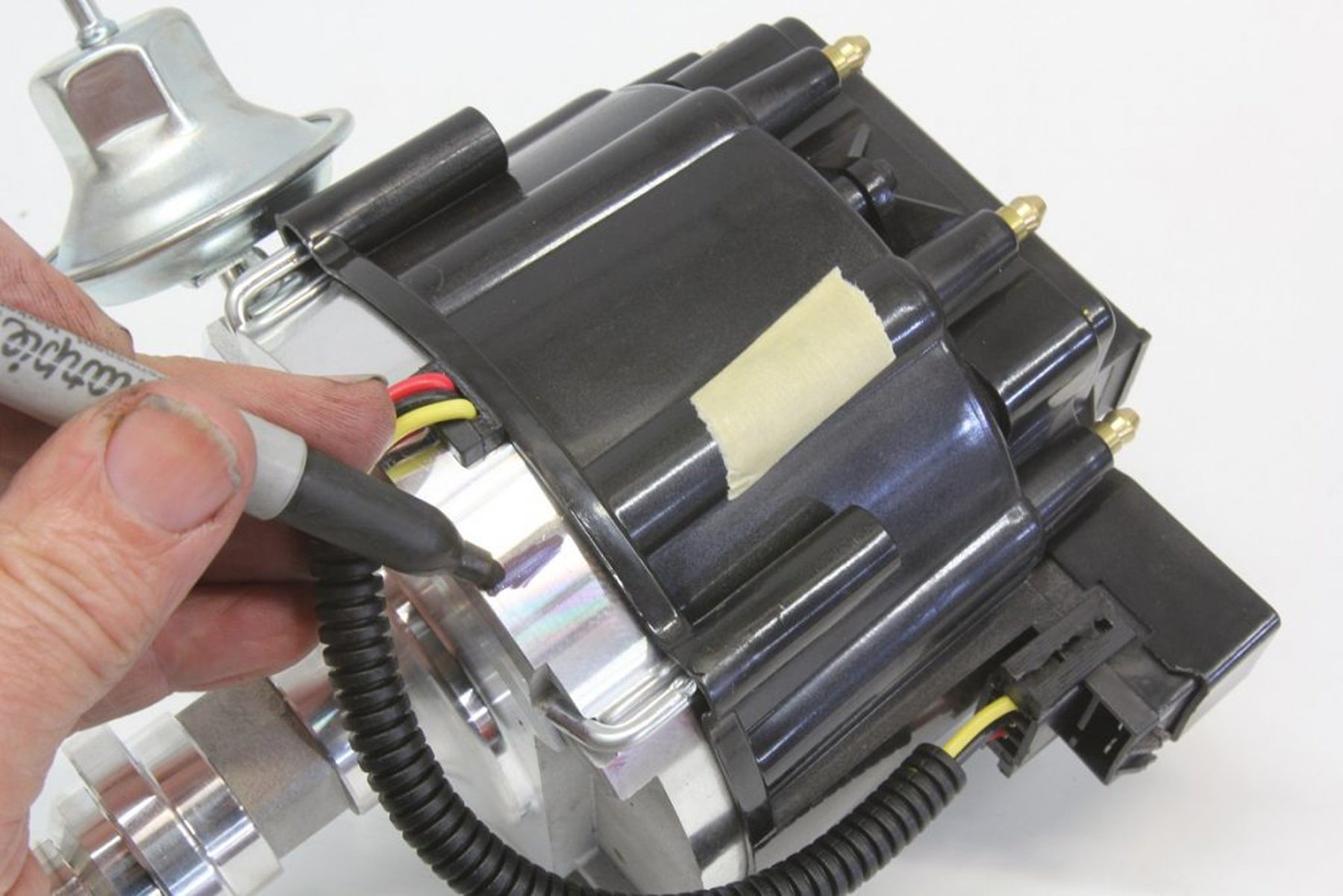

- Carefully lift off the distributor cap and expose the ignition module beneath it.

Testing The Ignition Module Using A Multimeter

Using a multimeter, you can perform a series of tests to assess the functionality of the ignition module. Here’s how:

- Set your multimeter to measure resistance (ohms).

- Locate the two terminals on the ignition module where the pickup coil connects. These are usually labeled “batt” and “tach.”

- Place the multimeter’s positive lead on the “batt” terminal and the negative lead on the “tach” terminal.

- Note the reading on the multimeter. A resistance reading between 0.6 and 1.6 ohms indicates a functioning ignition module.

- Repeat this process for the second set of terminals, typically labeled “w” and “g.”

- Compare the second reading with the specifications provided by the manufacturer. If it falls within the acceptable range, the ignition module is likely operational.

Analyzing The Test Results And Interpreting The Readings

Once you’ve conducted the necessary tests and obtained readings from the multimeter, it’s important to analyze them accurately. Here’s how to interpret the results:

- If the resistance readings for both sets of terminals fall within the specified ranges, the ignition module is most likely functioning correctly.

- In case the readings deviate from the acceptable range or show an open circuit (infinite resistance), the ignition module is likely faulty and needs to be replaced.

Troubleshooting And Diagnosing Potential Issues

If the tests indicate a faulty ignition module, it’s necessary to troubleshoot and diagnose potential issues. Here are a few common problems that may arise:

- Loose connections: Check for loose or corroded connections between the ignition module, distributor cap, and pickup coil. Ensure they are clean and securely attached.

- Excessive heat: Overheating can cause ignition modules to fail. Check for any signs of heat damage, such as discoloration or melted components.

- Wiring issues: Inspect the wiring harness connected to the ignition module for any signs of damage or fraying. Repair or replace any compromised wires.

Replacing A Faulty Ignition Module

If all troubleshooting attempts fail, and you’ve determined that the ignition module is indeed faulty, it’s time to replace it. Here’s how to go about the replacement process:

- Purchase a compatible replacement ignition module that matches the specifications of your hei distributor and engine.

- Follow the steps mentioned earlier to safely disconnect the battery and access the ignition module.

- Remove the defective ignition module by unscrewing or unclipping it from the distributor.

- Install the new ignition module and secure it properly using screws or clips.

- Reassemble the distributor cap, ensuring it is aligned correctly.

- Reconnect the battery, starting with the positive terminal followed by the negative terminal.

By following this step-by-step guide, you can effectively test, troubleshoot, and replace a faulty ignition module on a hei distributor. Remember to prioritize safety throughout the process and consult a professional if needed.

Tips For A Successful Ignition Module Test

Precautions To Take Before Testing The Ignition Module

Before starting the ignition module test on your hei distributor, it is essential to take a few precautions to ensure a successful and safe process. Here are the key points to keep in mind:

- Disconnect the battery: Before doing anything, it’s crucial to disconnect the battery and remove the ignition coil wire from the distributor cap. This will prevent any accidental starting of the engine while performing the test.

- Wear protective gear: To protect yourself from potential hazards and electrical shocks, it’s recommended to wear safety goggles and insulated gloves. These precautions ensure your well-being throughout the testing process.

- Inspect for physical damage: Before removing the ignition module, visually inspect it for any signs of physical damage such as cracks, corrosion, or burnt components. If you notice any issues, it’s best to replace the module before proceeding with the test.

- Follow proper grounding procedures: Ensure that the distributor is properly grounded by correctly connecting all the ground wires. This step helps in obtaining accurate test results and avoids any electrical interference.

- Be cautious of hot engine components: Since the ignition module is located within the distributor, it can be close to other hot engine components. Take care not to touch any parts that may cause burns while accessing the module for testing.

Troubleshooting Common Challenges During The Testing Process

During the ignition module test, you may encounter a few common challenges. Here are some troubleshooting tips to overcome these hurdles:

- Faulty connections: Ensure that all the electrical connections are secure and tight. Loose or corroded connections can affect the performance of the ignition module. Check and reattach any loose wires to their proper terminals.

- Weak spark: If you notice a weak or no spark during the test, it could indicate a problem with the ignition module. Check the module’s primary and secondary wiring connections and replace any worn-out components if necessary.

- Misfiring or rough idling: In some cases, a faulty ignition module can cause misfiring or rough idling of the engine. If you experience these symptoms, test the module using a digital multimeter to measure its primary and secondary circuit resistance values.

- Inconsistent timing: A malfunctioning ignition module can result in inconsistent timing, leading to poor engine performance. Verify the module’s base timing and adjust it according to the manufacturer’s specifications if needed.

- Overheating: Overheating can be a sign of a failing ignition module. If the module becomes excessively hot during testing, it may indicate a faulty component. Consider replacing the module to ensure optimal ignition system performance.

By following these precautions and troubleshooting tips, you’ll be well-equipped to test the ignition module on your hei distributor. Remember to refer to your vehicle’s specific repair manual for detailed instructions and always prioritize safety during the testing process.

Frequently Asked Questions About Testing Ignition Module On A Hei Distributor

If you’re experiencing ignition-related problems with your hei distributor, the ignition module could be the culprit. Testing the ignition module is a crucial step to diagnose the issue and ensure your engine runs smoothly. Here are answers to some frequently asked questions about testing the ignition module on a hei distributor:

Can A Faulty Ignition Module Cause Other Ignition-Related Problems?

Yes, a faulty ignition module can result in various ignition-related problems. These issues can include:

- Engine misfires: A malfunctioning ignition module may fail to provide the spark required to ignite the fuel-air mixture in the combustion chamber, resulting in engine misfires.

- Hard starting: A faulty ignition module can make it difficult for the engine to start, as it may not generate the necessary spark at the right time.

- Stalling: In some cases, a failing ignition module can cause the engine to stall while driving, leading to inconvenient and potentially dangerous situations.

- Reduced engine performance: If the ignition module is not functioning properly, it can lead to a decrease in overall engine performance, resulting in sluggish acceleration and reduced power output.

- Increased fuel consumption: A malfunctioning ignition module may cause the engine to run inefficiently, leading to higher fuel consumption and decreased fuel efficiency.

What Are The Possible Reasons For A Failed Ignition Module Test?

When testing the ignition module on a hei distributor, a failed test can be attributed to several reasons, including:

- Internal component failure: Over time, internal components within the ignition module can wear out or become damaged, leading to a failed test.

- Overheating: Heat is a common enemy of electronic components. Excessive heat can cause the ignition module to malfunction, resulting in a failed test.

- Moisture or water damage: Exposure to moisture or water can cause the ignition module to short circuit or corrode, leading to a failed test.

- Wiring issues: Faulty wiring connections or damaged wiring harnesses can disrupt the flow of electricity to the ignition module, causing it to fail the test.

- Power supply problems: If the ignition module is not receiving a proper power supply or if the voltage is incorrect, it can lead to a failed test.

It’s important to note that these are just a few possible reasons for a failed ignition module test. To accurately diagnose the issue, it is recommended to consult a professional or refer to the manufacturer’s guidelines for specific troubleshooting steps.

Remember, testing the ignition module is an essential part of troubleshooting ignition problems in your hei distributor. By understanding the potential issues and causes behind a failed test, you can effectively address the problem and get your engine running smoothly once again.

Frequently Asked Questions Of How To Test Ignition Module On A Hei Distributor

How Do You Test An Ignition Module On A Hei Distributor?

To test an ignition module on a hei distributor, you can use a multimeter to check for resistance readings and continuity in the module’s components.

What Are The Common Symptoms Of A Faulty Ignition Module?

Common symptoms of a faulty ignition module include engine misfires, stalling, rough idling, and difficulty starting the vehicle.

Can A Bad Ignition Module Cause A No Spark Condition?

Yes, a bad ignition module can cause a no spark condition, resulting in the engine not starting or running properly.

How Often Should You Replace The Ignition Module On A Hei Distributor?

The ignition module on a hei distributor can last for several years, but it’s recommended to replace it if you experience any issues related to ignition or if it fails diagnostic tests.

Can You Replace The Ignition Module On A Hei Distributor Yourself?

Yes, you can replace the ignition module on a hei distributor yourself by following the manufacturer’s instructions and using the appropriate tools.

Conclusion

To sum up, testing the ignition module on a hei distributor is a crucial step in troubleshooting ignition issues in your vehicle. By following the step-by-step process outlined in this blog, you can easily diagnose whether your ignition module is functioning properly or if it needs to be replaced.

Remember to take safety precautions and use a multimeter to accurately measure voltage and resistance. Being able to test and diagnose ignition module problems can save you time and money by avoiding unnecessary repairs or component replacements. Ignition module issues can cause various symptoms such as misfires, stalling, and weak spark, so it is essential to address them promptly.

With the knowledge gained from this blog post, you can confidently tackle ignition module testing and keep your vehicle running smoothly. Happy troubleshooting!

- How Much Does a Ford 9N Tractor Weigh - May 20, 2024

- How Many of My Exact Car were Made: Uncovering the Rarity - May 20, 2024

- How to Find Out What Someone Drives: Discover the Truth - May 20, 2024