To determine how far to press on the power steering pulley, refer to the vehicle’s manual or consult a professional technician. It is important to follow manufacturer guidelines for proper operation.

Maintaining the power steering system in your vehicle is crucial for effortless maneuverability. The power steering pulley plays a vital role in this system, ensuring that you can easily steer your vehicle in any direction. However, knowing how far to press on the power steering pulley is paramount to prevent damage or malfunction.

We will provide valuable insights on determining the appropriate amount of pressure to apply to the power steering pulley. By following the recommended guidelines, you can extend the lifespan of your power steering system and enjoy a smooth and safe driving experience.

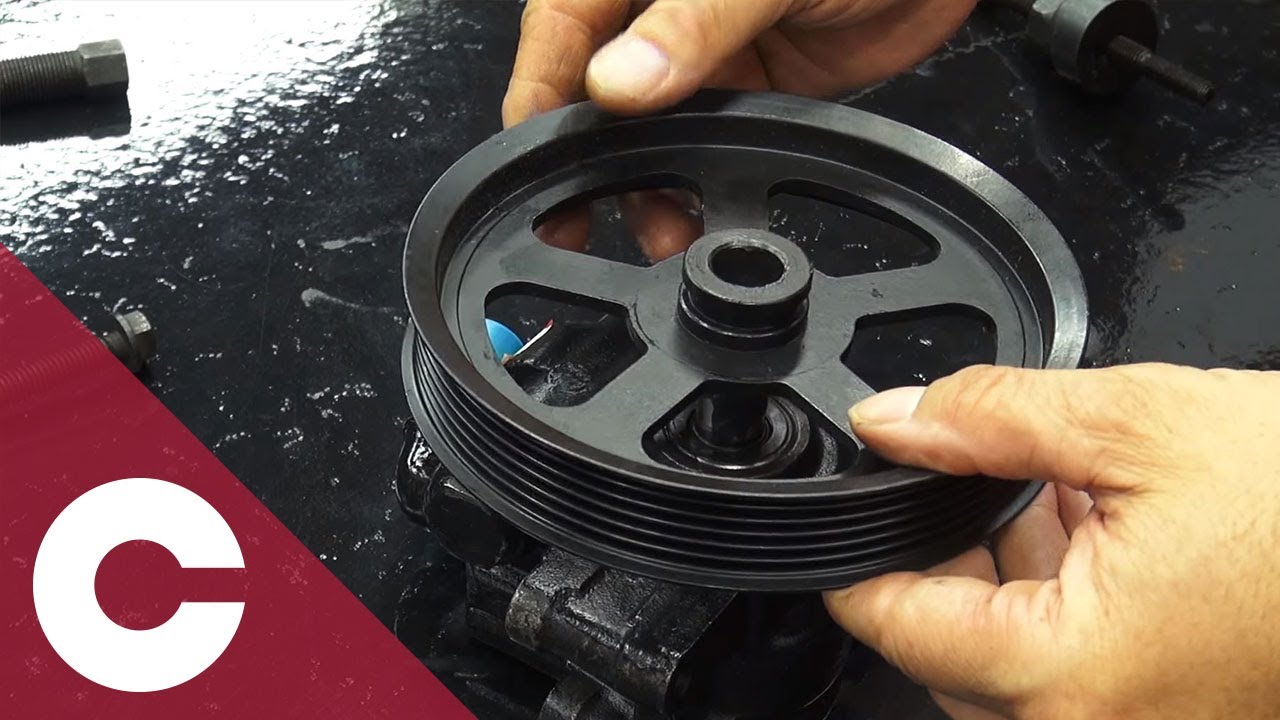

Credit: www.youtube.com

Understanding Power Steering Pulley Pressing

The power steering pulley plays a crucial role in the steering system of your vehicle. It is responsible for transmitting power from the engine to the power steering pump, allowing you to effortlessly turn the wheels. But have you ever wondered about the importance of proper power steering pulley pressing?

In this section, we will delve into the significance of this process and the factors that should be considered when pressing on a power steering pulley.

Importance Of Proper Power Steering Pulley Pressing

Pressing on the power steering pulley correctly is essential to ensure optimal performance and longevity of your steering system. Here are a few reasons why it’s crucial to pay attention to this process:

- Secure power transmission: Proper pressing of the power steering pulley ensures a secure connection between the pulley and the power steering pump shaft. This secure connection allows for efficient power transmission, enabling smooth and responsive steering.

- Prevents pulley slippage: If the power steering pulley is not pressed on properly, it may lead to pulley slippage. This can occur when the pulley is not securely aligned with the shaft, causing it to slide or rotate loosely. Pulley slippage can result in a loss of power steering functionality and negatively impact the steering performance of your vehicle.

- Reduces noise and vibration: A well-pressed power steering pulley minimizes unnecessary noise and vibration in the steering system. By ensuring a proper fit, you can reduce the risk of pulley wobbling or rattling, resulting in a quieter and more comfortable driving experience.

The Role Of Power Steering Pulley In The Steering System

The power steering pulley serves as a crucial component in the overall functioning of the steering system. Here are a few key roles it plays:

- Power transfer: The power steering pulley acts as a medium to transfer power from the engine to the power steering pump. It connects the engine’s rotational force to the hydraulic system of the power steering, allowing for easy steering control.

- Belt-driven operation: The power steering pulley is driven by a serpentine or v-belt connected to the engine’s crankshaft pulley. As the engine runs, the rotational force of the belt is transferred to the power steering pump via the pulley, assisting in steering maneuvers.

- Maintaining system pressure: The power steering pulley assists in maintaining the necessary hydraulic pressure within the power steering system. This pressure allows for precise control of the steering mechanism, ensuring smooth and responsive steering.

Factors To Consider When Pressing On A Power Steering Pulley

When pressing on a power steering pulley, several factors need to be taken into account to ensure a proper fit and optimal performance. Consider the following:

- Compatibility: Ensure that the power steering pulley is compatible with your specific vehicle make and model. Different vehicles may have variations in pulley designs and specifications.

- Alignment: Proper alignment of the pulley with the power steering pump shaft is essential. Confirm that the pulley sits flush against the shaft without any misalignment or gaps.

- Correct tools: Utilize appropriate tools specifically designed for power steering pulley pressing. This helps to ensure that the pulley is pressed on evenly and securely, avoiding any damage.

- Torque specifications: Follow the manufacturer’s recommended torque specifications for pressing on the power steering pulley. This ensures that the pulley is tightened to the appropriate level, preventing any issues in the future.

By understanding the importance of proper power steering pulley pressing, recognizing the role of the power steering pulley in the steering system, and considering the necessary factors, you can maintain the optimal performance of your vehicle’s steering system.

Tools And Equipment For Power Steering Pulley Pressing

When it comes to pressing on a power steering pulley, having the right tools and equipment is essential. Not only does it make the task easier, but it also ensures that the job is done correctly and safely. In this section, we will discuss the necessary tools and equipment for power steering pulley pressing and provide tips on their maintenance, storage, and safety precautions.

Essential Tools And Equipment Required For The Task:

- Power steering pulley press tool: This specialized tool is designed to securely fit and press on power steering pulleys. It provides the necessary force to properly install or remove the pulley without causing any damage.

- Socket set: A set of sockets in various sizes is needed to remove and tighten bolts and nuts during the power steering pulley pressing process.

- Torque wrench: A torque wrench is used to ensure that the bolts are tightened to the manufacturer’s specified torque value. It prevents over or under tightening, which can lead to pulley damage or failure.

- Pulley puller tool: In some cases, a pulley puller may be required to remove a stubborn pulley. This tool helps to safely and effectively remove the pulley without causing any damage to the power steering system.

Proper Maintenance And Storage Of Tools:

- Keep tools clean and free from debris: After each use, wipe down the tools to remove any dirt, grease, or debris. This prevents build-up and keeps the tools in good working condition.

- Store tools in a dry and secure location: Moisture can cause tools to rust or corrode, so it is important to store them in a dry environment. Additionally, ensure that the tools are stored securely to prevent damage or loss.

- Regularly inspect tools for damage: Before each use, inspect the tools for any damage such as cracks, worn-out parts, or loose fittings. Damaged tools should be repaired or replaced immediately to prevent accidents or further damage.

Safety Precautions When Using Tools For Power Steering Pulley Pressing:

- Always wear safety goggles and gloves: Protect your eyes and hands by wearing safety goggles and gloves while operating power steering pulley press tools. This will help prevent injuries from flying debris or accidental contact.

- Follow manufacturer’s instructions: Familiarize yourself with the user manual and instructions provided by the tool manufacturer. Adhere to the recommended techniques, safety guidelines, and usage limitations to ensure proper and safe operation.

- Use the right tool for the job: Use only tools that are specifically designed for power steering pulley pressing. Using inappropriate tools can lead to damage to the pulley or injury to yourself.

- Secure the work area: Before starting, make sure the work area is clear of any obstacles or hazards that could cause accidents or interfere with the pressing process. This includes removing any loose objects, ensuring a stable work surface, and securing the vehicle to prevent movement.

By having the essential tools and equipment for power steering pulley pressing, properly maintaining and storing them, and following safety precautions, you can ensure a smooth and successful pulley installation or removal process. Remember to always prioritize safety and adhere to the recommended guidelines to prevent accidents and costly damages.

Step-By-Step Guide To Pressing On A Power Steering Pulley

Preparing the vehicle and workspace for the task:

- Park the vehicle on a flat and stable surface to ensure safety during the process.

- Place wheel chocks behind the rear tires to prevent any accidental movement.

- Open the vehicle’s hood and locate the power steering pump.

Removing the old power steering pulley:

- Loosen the serpentine belt tensioner to relieve tension on the power steering pump pulley.

- Use a wrench to disconnect the power steering pump pulley from the pump shaft, turning it counterclockwise.

- Carefully remove the old pulley from the shaft, ensuring not to damage any surrounding components.

Inspecting and cleaning the pulley and shaft:

- Examine the new power steering pulley for any defects, such as cracks or chips. If found, do not proceed with installation and contact the supplier.

- Clean the pump shaft using a lint-free cloth to remove any debris or dirt.

- Inspect the shaft for any damage or wear. If observed, it may be necessary to replace the shaft along with the pulley.

Aligning the new pulley onto the shaft:

- Place the new power steering pulley onto the pump shaft, ensuring it fits snugly.

- Ensure that the pulley sits flush against the flange on the pump shaft.

- Gently wiggle the pulley back and forth to confirm proper alignment.

Applying the appropriate pressure for pressing:

- If necessary, use a power steering pulley installation tool to press the pulley onto the shaft.

- Align the tool correctly, ensuring it engages with both the pump shaft and the pulley.

- Gradually apply pressure, exerting force until the pulley is fully seated on the shaft.

Verifying the proper installation of the power steering pulley:

- Double-check that the pulley is securely attached to the pump shaft.

- Rotate the pulley by hand to confirm smooth and unrestricted movement.

- Inspect the belt alignment to ensure it is properly positioned on all pulleys.

Remember, the power steering pulley plays a vital role in the functioning of the power steering system, so it is essential to follow this step-by-step guide carefully. By doing so, you can ensure that the replacement process is carried out correctly, leading to optimal performance and longevity of your power steering system.

Happy repairing!

Troubleshooting Common Issues During Power Steering Pulley Pressing

Whether you’re a seasoned mechanic or a diy enthusiast, dealing with power steering pulley pressing can sometimes present challenges. From misaligned pulleys to excessive or insufficient pressure, it’s essential to be well-prepared to troubleshoot and address these common issues. Additionally, the handling of damaged or worn-out pulleys, as well as resolving noise or vibration problems after installation, is crucial.

Let’s delve into each of these areas to ensure a smooth power steering pulley pressing experience.

Identifying And Addressing Pulley Misalignment

When it comes to power steering pulley pressing, one key issue you may encounter is pulley misalignment. Here are a few points to consider:

- Ensure that the pulley is centered correctly on the power steering pump shaft.

- Check for any signs of wobbling or uneven alignment, which could indicate a misaligned pulley.

- If misalignment is detected, use a puller tool to reintegrate the pulley back into alignment.

- Remember to apply steady pressure and make gradual adjustments to avoid damaging the pulley or other components.

Dealing With Excessive Or Insufficient Pressure

Excessive or insufficient pressure during power steering pulley pressing can lead to various complications. Here’s what you need to know:

- Excessive pressure risks damaging the pump shaft or other components.

- Insufficient pressure may result in an improperly seated pulley that can loosen over time.

- To achieve the appropriate pressure, consider using a specialized tool designed for power steering pulley pressing.

- Follow the manufacturer’s instructions and apply moderate and controlled force until the pulley is fully seated.

Handling Damaged Or Worn-Out Pulleys

Old or damaged pulleys can interfere with the proper functioning of your power steering system. Take note of the following:

- Inspect the pulley for signs of wear, cracks, or damage before installation.

- Replace any worn-out or damaged pulleys with new ones to ensure optimal performance.

- When installing a new pulley, ensure it matches the specifications of your power steering pump.

- Use the appropriate techniques and tools to smoothly press the new pulley onto the shaft without causing unnecessary strain.

Resolving Noise Or Vibration Issues After Installation

After successfully pressing the power steering pulley, it’s essential to address any noise or vibration problems that may arise. Consider the following tips:

- Excessive noise or vibration can suggest an alignment issue or inadequate pressing.

- Inspect the pulley carefully to ensure it is properly seated and aligned.

- Verify that all attaching bolts are securely tightened.

- If the issue persists, it may be necessary to disassemble and reassemble the power steering pump, following the manufacturer’s guidelines.

Troubleshooting common issues during power steering pulley pressing requires attention to detail and a systematic approach. By identifying and addressing pulley misalignment, dealing with excessive or insufficient pressure, handling damaged or worn-out pulleys, and resolving noise or vibration issues, you can ensure a successful installation and optimal performance of your power steering system.

Remember to follow the manufacturer’s instructions and take your time to achieve the desired results.

Expert Tips And Recommendations For Power Steering Pulley Pressing

When it comes to pressing on a power steering pulley, there are certain tips and recommendations from experts that can make the process smoother and more effective. From using specific lubricants or adhesives to avoiding common mistakes, these guidelines can help ensure a successful installation.

Let’s dive into the details:

Using Specific Lubricants Or Adhesives For Better Installation

- Apply a light coat of lubricant on the shaft of the power steering pump and the inside of the pulley. This will help facilitate the pressing process and prevent any unnecessary friction.

- Choose a high-quality adhesive that is specifically designed for power steering pulleys. This will enhance the bond between the pulley and the shaft, providing secure and long-lasting installation.

Checking The Manufacturer’S Guidelines For Specific Torque Specifications

- Refer to the manufacturer’s guidelines or specifications for the recommended torque values when pressing on the power steering pulley. This ensures that the pulley is securely attached and prevents any issues related to under or over tightening.

- Use a torque wrench to achieve the specified torque. This tool allows for precise application of force, avoiding any potential damage to the pulley or the power steering pump.

Avoiding Common Mistakes During The Pressing Process

- Ensure that the power steering pump shaft and pulley are clean and free from debris before pressing. This will prevent any particles from interfering with the installation and potentially causing damage.

- Use a proper pulley installation tool or a suitable makeshift tool to evenly distribute force while pressing. This helps prevent any unintended misalignment or damage to the pulley or the power steering system.

Regular Maintenance And Inspection To Prevent Future Issues

- Conduct periodic inspections of the power steering pulley and the entire power steering system. Look out for any signs of wear, such as excessive noise or wobbling, and address them promptly to prevent further damage.

- Regularly check the tightness of the power steering pulley to ensure it remains securely attached. If any looseness or movement is detected, re-torque the pulley following the manufacturer’s guidelines.

With these expert tips and recommendations, you can press on a power steering pulley effectively and prevent future issues. Remember to use suitable lubricants or adhesives, follow the manufacturer’s torque specifications, avoid common mistakes, and conduct regular maintenance and inspections.

By following these guidelines, you can ensure a smooth and trouble-free power steering system operation.

Frequently Asked Questions About Power Steering Pulley Pressing

When it comes to the power steering system, the power steering pulley plays a crucial role in the proper functioning of the system. Over time, it may become necessary to replace or reinstall the power steering pulley. If you’re wondering about the process and its implications, here are some frequently asked questions and their answers to help you understand more:

How Often Should Power Steering Pulleys Be Replaced?

- Power steering pulleys generally do not need to be replaced as part of regular maintenance.

- Replacement should only be considered if the pulley shows signs of damage, such as cracks or excessive wear.

- Regular inspection of the power steering pulley is recommended during routine maintenance to catch any potential issues early on.

Can I Reuse The Old Power Steering Pulley?

- It is generally not recommended to reuse the old power steering pulley when replacing or working on the power steering system.

- Reusing the old pulley may not provide a secure and reliable connection, leading to potential issues down the line.

- It is advisable to use a new power steering pulley during installation to ensure optimal performance and longevity of the system.

Are There Alternative Methods For Installing Power Steering Pulleys?

- While pressing the power steering pulley onto the power steering pump shaft is the most common method of installation, there are alternative methods available.

- Some alternative methods include using a pulley installation tool or a hydraulic press to apply even pressure and secure the pulley in place.

- It is important to follow the manufacturer’s instructions or consult a professional to determine the most suitable method for your specific power steering pulley and vehicle.

What Are The Consequences Of Improper Power Steering Pulley Pressing?

- Improper power steering pulley pressing can lead to various issues that affect the performance and functionality of the power steering system.

- The pulley may become loose, causing vibrations and noise during operation.

- If the pulley is not securely pressed onto the power steering pump shaft, it can cause damage to the pump itself or result in premature wear of the pulley.

- In extreme cases, improper pulley pressing can lead to total failure of the power steering system, resulting in loss of power assist and difficulty in steering.

Remember, when working on the power steering pulley or any part of the power steering system, it is always recommended to follow the manufacturer’s guidelines or consult a professional for proper installation and maintenance. By ensuring the correct pressing of the power steering pulley, you can maintain a smooth and efficient power steering experience.

Frequently Asked Questions Of How Far To Press On Power Steering Pulley

How Do You Know If Your Power Steering Pulley Is Bad?

A bad power steering pulley may show symptoms such as difficulty in steering, strange noises, or fluid leakage.

Can You Drive With A Bad Power Steering Pulley?

Driving with a bad power steering pulley is not recommended as it can lead to loss of power steering functionality.

What Causes A Power Steering Pulley To Go Bad?

Common causes for a power steering pulley to go bad include wear and tear, damaged bearings, or belt misalignment.

How Far Should You Press On The Power Steering Pulley?

Pressing on the power steering pulley should be done with enough force to engage and secure it in place.

Do Power Steering Pulleys Need To Be Replaced?

Power steering pulleys may need to be replaced if they are malfunctioning, damaged, or exhibiting signs of wear.

Conclusion

Understanding the proper amount of pressure to apply to a power steering pulley is crucial for maintaining the health and functionality of your vehicle. By exerting too much force, you risk damaging the pulley or even the entire power steering system, resulting in costly repairs.

Conversely, insufficient pressure can lead to steering issues and a lack of control over your vehicle. It is important to follow manufacturer guidelines and use the appropriate tools to ensure the correct amount of force is applied to the power steering pulley during installation or replacement.

Regularly inspecting the pulley for any signs of wear or damage is also essential for preventative maintenance. Remember, by taking the time to properly press on the power steering pulley, you are ensuring the longevity and reliability of your vehicle’s steering system.