Have you ever wondered about the intricate workings of a car’s engine? One crucial component that often goes unnoticed is the manifold. But how many manifolds does a car actually have? In this article, we will delve into the fascinating world of automotive engineering to uncover the answer.

When you pop open the hood of your car, you might be overwhelmed by the maze of machinery and components. Among these, the manifold quietly plays a vital role in ensuring your vehicle’s optimal performance. But what exactly is a manifold? In simple terms, it is a device that distributes or collects fluid, air, or exhaust gases within an engine. It connects various parts of the engine, facilitating the smooth flow of these elements. However, the exact number of manifolds in a car can vary depending on the type of engine and its design. To truly understand the manifold’s significance, let’s embark on an exploration of the diverse manifolds found in different car engines.

A car typically has two main types of manifolds: the intake manifold and the exhaust manifold. The intake manifold delivers air and fuel to the engine cylinders, while the exhaust manifold collects and expels the exhaust gases. These manifolds play crucial roles in the engine’s performance and efficiency.

How Many Manifolds Does a Car Have?

In a car, there are several manifolds that play a crucial role in the functioning of the vehicle. Manifolds are essential components that help optimize the performance of the engine and ensure its efficient operation. Let’s explore the different manifolds found in a typical car and their respective functions.

The Intake Manifold

The intake manifold is responsible for delivering the air-fuel mixture to the engine cylinders. It is connected to the throttle body, which regulates the amount of air entering the engine. The intake manifold ensures the even distribution of the mixture to each cylinder, allowing for efficient combustion. Typically, it is made of aluminum or plastic and is designed to minimize restrictions and maximize airflow.

Additionally, some modern car engines feature an intake manifold with variable length runners. These runners can change their length to optimize airflow at different engine speeds, improving performance and fuel efficiency.

The Exhaust Manifold

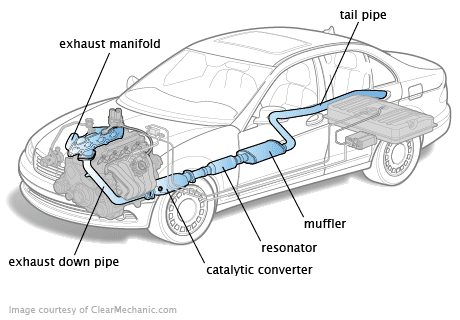

The exhaust manifold is located on the engine’s cylinder head and is responsible for collecting and directing the exhaust gases away from the engine. It is connected to the exhaust ports of the cylinders and channels the gases to the exhaust system. The primary function of the exhaust manifold is to ensure the efficient removal of exhaust gases while minimizing backpressure.

Exhaust manifolds are typically made of cast iron or stainless steel to withstand high temperatures. Some aftermarket options are designed for improved performance, featuring better airflow and reduced weight.

The EGR (Exhaust Gas Recirculation) Manifold

In certain cars, an EGR manifold is present to facilitate the recirculation of a portion of the exhaust gases back into the engine cylinders. The EGR system helps reduce nitrogen oxide emissions by diluting the incoming air-fuel mixture with inert exhaust gases. The EGR manifold connects the EGR valve to the intake manifold and ensures the proper mixing of exhaust gases with the fresh intake charge.

The EGR manifold is usually made of cast iron or aluminum, and its design aims to optimize the flow of gases and prevent the buildup of carbon deposits.

The Turbocharger Manifold

In turbocharged cars, there is an additional manifold known as the turbocharger manifold or the exhaust manifold. This manifold is specifically designed to direct exhaust gases towards the turbocharger, which compresses the incoming air for improved engine performance. The turbocharger manifold plays a crucial role in ensuring a smooth and efficient flow of exhaust gases to the turbocharger.

Depending on the specific turbocharger setup, the manifold can be made of cast iron or stainless steel and may feature integrated wastegates or other components for optimal turbocharger control.

The Power Steering Manifold

In cars equipped with power steering systems, a power steering manifold is used to supply hydraulic fluid to the power steering pump. This manifold ensures the proper flow and pressure of the fluid, allowing for smooth and effortless steering. It connects the power steering pump to the steering gear or rack, enabling the transfer of hydraulic force to assist with steering maneuvers.

The power steering manifold is typically made of aluminum or steel, and its design may vary depending on the specific power steering system in the vehicle.

The Cooling System Manifold

The cooling system manifold, also known as the coolant manifold or thermostat housing, is responsible for distributing coolant throughout the engine. It connects the engine block to the radiator and ensures the proper flow of coolant to regulate engine temperature. The cooling system manifold also houses the thermostat, which controls the flow of coolant based on the engine’s temperature.

These manifolds are usually made of aluminum or plastic, and their design incorporates channels and passages to direct coolant flow efficiently.

The Fuel Rail Manifold

The fuel rail manifold plays a crucial role in delivering fuel to the engine’s fuel injectors. It connects the fuel injectors to the fuel supply line and ensures the consistent supply of fuel at the required pressure. The fuel rail manifold is responsible for maintaining fuel flow and pressure within the engine’s specifications, allowing for proper combustion.

These manifolds are typically made of aluminum or stainless steel and feature integrated fuel pressure regulators and sensors for precise fuel delivery.

The HVAC (Heating, Ventilation, and Air Conditioning) Manifold

In cars equipped with HVAC systems, an HVAC manifold is used to distribute heating and cooling air to different parts of the vehicle. It connects the HVAC unit to the various air ducts, allowing for the regulation of temperature and airflow. The HVAC manifold ensures that the conditioned air reaches the desired locations inside the car, providing comfort to the passengers.

These manifolds are usually made of plastic or aluminum and feature connections for the different HVAC components, such as the heater core, evaporator, and blower motor.

The Brake Manifold

In cars equipped with hydraulic brake systems, a brake manifold is used to distribute brake fluid to the different brake calipers or wheel cylinders. It ensures the proper supply of hydraulic pressure to each brake, allowing for effective braking performance. The brake manifold is typically connected to the master cylinder and routes the brake fluid to the individual brake components.

Brake manifolds are usually made of steel or aluminum and feature connections for the brake lines and fittings.

The Vacuum Manifold

A vacuum manifold is present in some cars to distribute vacuum pressure to various components that require it for operation. It connects the vacuum source, such as the intake manifold, to the different vacuum-dependent devices, such as the brake booster, HVAC controls, and emission control systems. The vacuum manifold ensures the proper functioning of these components by providing the necessary vacuum pressure.

These manifolds are typically made of plastic or aluminum and feature connections for the vacuum lines and fittings.

These are the main manifolds found in a typical car, each serving a specific purpose and contributing to the overall performance and functionality of the vehicle.

Frequently Asked Questions

In this section, we will answer some common questions about the number of manifolds in a car.

Question 1: How many manifolds does a car typically have?

Answer: A car usually has two main types of manifolds – the intake manifold and the exhaust manifold. The intake manifold is responsible for distributing the air-fuel mixture to the engine cylinders, while the exhaust manifold collects and channels the exhaust gases out of the engine. So, in total, a car typically has two manifolds.

However, it’s important to note that some high-performance or modified cars may have additional manifolds, such as turbocharger or supercharger manifolds, which are used to increase engine power. These additional manifolds are not present in all cars and depend on the specific engine configuration and modifications.

Question 2: What is the function of the intake manifold?

Answer: The intake manifold plays a crucial role in the combustion process of a car’s engine. Its main function is to evenly distribute the air-fuel mixture to each cylinder for efficient combustion. The intake manifold is connected to the throttle body, which regulates the amount of air entering the engine. It also contains passages or runners that direct the air-fuel mixture to each cylinder.

The design of the intake manifold affects the engine’s performance, as it determines factors such as the airflow velocity, volume, and distribution. By optimizing these factors, the intake manifold can improve the engine’s power, torque, and fuel efficiency.

Question 3: What is the purpose of the exhaust manifold?

Answer: The exhaust manifold serves the important function of collecting the exhaust gases produced during the combustion process and channeling them out of the engine. It is directly connected to the engine cylinders and is usually made of cast iron or stainless steel for durability and heat resistance.

The exhaust manifold’s design is critical for efficient exhaust gas flow and to minimize backpressure, which can restrict the engine’s performance. It is often shaped with individual passages for each cylinder and may incorporate features such as merge collectors or tuned-length runners to optimize exhaust gas scavenging and improve overall engine performance.

Question 4: Can a car have more than two manifolds?

Answer: Yes, some cars, especially high-performance or modified vehicles, can have additional manifolds. These additional manifolds are often associated with forced induction systems, such as turbochargers or superchargers. Turbocharger manifolds, also known as exhaust manifolds, are designed to direct exhaust gases to drive the turbine and increase engine power. Supercharger manifolds, on the other hand, are responsible for distributing compressed air to the engine for enhanced performance.

It’s important to note that not all cars have these additional manifolds. Their presence depends on the specific engine configuration and modifications made to the vehicle.

Question 5: Can the number of manifolds affect a car’s performance?

Answer: Yes, the number and design of manifolds can have a significant impact on a car’s performance. The intake manifold, for example, plays a vital role in delivering the air-fuel mixture to the engine cylinders. An optimized intake manifold design can improve airflow, resulting in increased power and torque.

Similarly, the exhaust manifold’s design affects the engine’s ability to expel exhaust gases efficiently. A well-designed exhaust manifold reduces backpressure, allowing the engine to breathe better, resulting in improved performance. Additionally, the presence of additional manifolds, such as turbocharger or supercharger manifolds, can enhance engine power by increasing air or exhaust gas flow.

Intake Manifold – Explained

In conclusion, understanding the different components and systems of a car is essential for any automobile enthusiast or aspiring mechanic. When it comes to manifolds, a car typically has several, each serving a specific purpose. From the intake manifold that delivers air and fuel to the engine, to the exhaust manifold that expels the exhaust gases, these components play a crucial role in the overall performance and efficiency of a vehicle.

Whether you are a car owner wondering about the number of manifolds in your vehicle or simply curious about the inner workings of automobiles, exploring the world of manifolds can be both fascinating and educational. By delving into the intricacies of these systems, you can gain a deeper appreciation for the engineering marvel that is the modern car. So, the next time you see a car on the road, take a moment to ponder the various manifolds hidden beneath the hood, and marvel at the complexity and ingenuity behind their design.