To test a tractor starter solenoid, use a multimeter to check for continuity and voltage. Then, energize the solenoid to ensure proper operation.

Testing the starter solenoid on a tractor is a crucial step in diagnosing starting issues. The solenoid is responsible for transferring electrical current from the battery to the starter motor, enabling the engine to crank. By following a few simple steps, you can determine if the solenoid is functioning correctly or if it needs to be replaced.

Proper maintenance of the starter solenoid ensures that your tractor starts smoothly and efficiently every time.

Credit: www.youtube.com

Common Problems With Tractor Starter Solenoids

Common problems with tractor starter solenoids often arise due to various issues with the component. Being able to identify and understand these problems is essential for maintaining the efficient functionality of your tractor. In this section, we will discuss the common problems with tractor starter solenoids and the signs of a faulty solenoid. Understanding these issues will enable you to know when to test the starter solenoid, ensuring that your tractor continues to operate smoothly.

Starter Solenoids And Their Function

A starter solenoid is a crucial part of the starting system in a tractor. Its primary function is to engage the starter gear with the flywheel of the engine, allowing the engine to turn over and start. The solenoid serves as a bridge between the tractor’s ignition switch and the starter motor, delivering the electrical current needed to activate the starter. Essentially, it is responsible for the initial action of the starting process, making it a vital component for the tractor’s operation.

Signs Of A Faulty Starter Solenoid

- Clicking noise: One of the most common signs of a faulty starter solenoid is a clicking noise when attempting to start the tractor. This indicates that the solenoid is engaging but failing to transfer the current to the starter motor.

- No response: Another indication of a faulty solenoid is when the tractor does not respond at all when the ignition key is turned. If there are no sounds or movements when attempting to start the tractor, it may be due to a malfunctioning solenoid.

- Intermittent starting: If the tractor’s starting process is inconsistent, with occasional success and failure, it may be a sign of a problematic solenoid. This erratic behavior can be a result of an unreliable connection within the solenoid.

Importance Of Testing The Starter Solenoid

Testing the starter solenoid is crucial for ensuring that the tractor’s starting system functions optimally. By diagnosing and addressing any issues with the solenoid, you can prevent potential starting failures and maintain the overall performance of your tractor. Regular testing and maintenance of the starter solenoid can extend its lifespan and contribute to the reliability of the tractor’s starting mechanism.

Safety Precautions Before Testing

Before testing the tractor starter solenoid, it is crucial to take safety precautions to avoid accidents and injuries. Following proper guidelines and wearing protective gear will ensure a safer testing process.

Disconnecting The Battery

Before testing the tractor starter solenoid, disconnect the battery to prevent any electrical hazards.

Wearing Protective Gear

Remember to always wear protective gear such as gloves and safety goggles to keep yourself safe.

Working In A Well-ventilated Area

Ensure you are working in a well-ventilated area to avoid inhaling any harmful fumes while testing the starter solenoid.

Testing The Tractor Starter Solenoid

When it comes to ensuring your tractor starts reliably, testing the tractor starter solenoid is crucial. Follow these steps to inspect and test the solenoid efficiently.

Inspecting The Solenoid Terminals

Begin by visually checking the solenoid’s terminals for any signs of corrosion or damage.

Checking For Continuity With A Multimeter

Use a multimeter to test for continuity between the solenoid terminals to verify if the electrical circuit is intact.

Conducting A Voltage Drop Test

Perform a voltage drop test by connecting the multimeter to the solenoid terminals to check for any voltage drops.

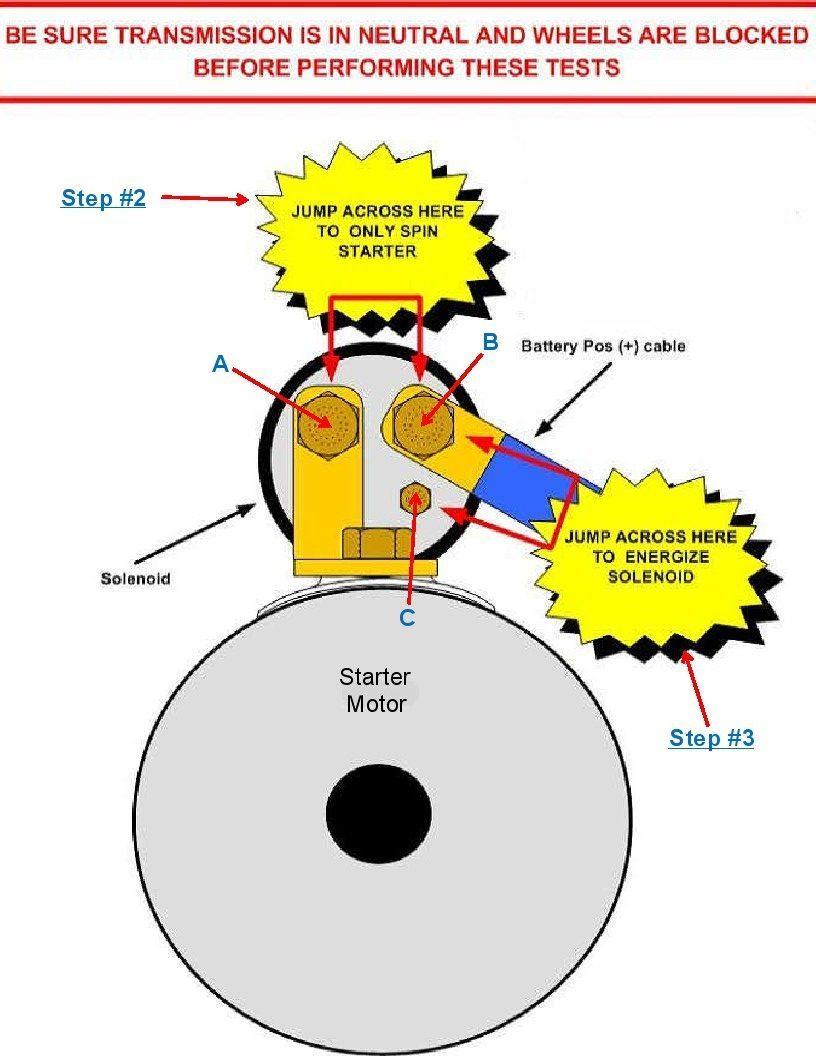

Testing The Solenoid With A Remote Starter Switch

Initiate a test by connecting a remote starter switch to the solenoid to ensure it engages properly.

Credit: www.circlegtractorparts.com

Interpreting The Test Results

Once the diagnostic testing of the tractor starter solenoid is complete, it’s crucial to interpret the test results accurately. This step is essential for identifying any potential issues and determining the necessary course of action.

Understanding Continuity Readings

Continuity readings are crucial in assessing the electrical flow within the starter solenoid. A multimeter can be used to measure the continuity across the various terminals of the solenoid. The presence of continuity indicates a clear path for electrical current, while a lack of continuity signifies a potential problem in the circuit.

Analyzing Voltage Drop Measurements

Measuring the voltage drop across different points of the starter solenoid provides insights into the overall efficiency of the electrical system. A high voltage drop could indicate resistance or corrosion, potentially impeding the flow of electricity.

Identifying Potential Issues Based On Test Results

- Consistent continuity readings and minimal voltage drop suggest a healthy electrical connection.

- If continuity readings are inconsistent or there is a significant voltage drop, this could indicate potential issues such as corrosion, worn-out components, or a faulty solenoid.

Replacing Or Repairing The Tractor Starter Solenoid

Determining If Repair Is Possible

If you suspect that your tractor’s starter solenoid is faulty, the first step is to determine if it can be repaired. This will depend on the extent of the damage and whether replacement parts are readily available. Follow these steps to assess the condition of the solenoid:

- Inspect the solenoid for any visible signs of damage, such as corrosion or loose connections. If you notice these issues, a simple repair may be possible.

- Use a multimeter to check the continuity of the solenoid’s electrical connections. If you find an open circuit or high resistance, it’s likely that the solenoid needs to be replaced.

- Consider the age and condition of the solenoid. If it is significantly worn out or has been repeatedly repaired in the past, it may be more cost-effective to replace it rather than attempting another repair.

Steps To Replace A Faulty Solenoid

If repairing the tractor starter solenoid is not possible or not practical, replacing it is the next best option. Follow these steps for a successful replacement:

- Start by locating the starter solenoid on your tractor. It is typically situated near the engine, usually on the side or top.

- Disconnect the negative battery cable to ensure safety while working on your tractor’s electrical system.

- Remove any wires or connections attached to the solenoid. Be sure to note their locations or take pictures for reference during reassembly.

- Take out the faulty solenoid by loosening the mounting bolts or screws that hold it in place. Gently lift the solenoid out of its position.

- Install the new solenoid by aligning it with the mounting holes and tightening the bolts or screws securely.

- Reconnect the wires and connections to their proper locations on the new solenoid. Use your reference pictures or notes to ensure correct reconnection.

- Reattach the negative battery cable to restore power to your tractor’s electrical system.

Proper Installation And Reconnection

Once the faulty solenoid has been replaced, it is crucial to ensure proper installation and reconnection. Follow these steps to prevent any potential issues:

- Double-check that all connections are securely tightened to minimize the risk of loose or faulty electrical connections.

- Inspect the wiring for any signs of wear or damage. Replace any compromised wires to maintain optimal electrical performance.

- Verify that the solenoid is correctly aligned with the mounting holes and sits in its designated position.

- Tighten the mounting bolts or screws securely but avoid over-tightening, which can cause damage.

Credit: www.youtube.com

Frequently Asked Questions For How To Test A Tractor Starter Solenoid

How Do You Diagnose A Bad Starter Solenoid?

To diagnose a bad starter solenoid, listen for a clicking sound when turning the key. Check for a voltage drop while attempting to start the engine. Inspect for loose connections or corrosion on the solenoid terminals. Test the solenoid by bypassing it and applying voltage.

How Do You Know If The Starter Solenoid Is Bad On A Lawn Tractor?

To determine if the starter solenoid is bad on a lawn tractor, listen for a clicking noise when turning the key. Check the battery for power and inspect the connections for corrosion or looseness. If issues persist, consult a professional for further diagnosis and repair.

How Do You Test A Solenoid On A Tractor?

To test a solenoid on a tractor, use a multimeter to check for continuity and resistance across its terminals. Apply power and ground to see if it clicks or engages. If it doesn’t, the solenoid may be faulty and need replacement.

How Do You Test A Starter Solenoid With A Multimeter?

To test a starter solenoid with a multimeter, set the multimeter to the ohms setting. Connect the positive lead to the solenoid’s terminal, and the negative lead to the housing. The multimeter should show continuity. If not, it may indicate a faulty solenoid.

Conclusion

Testing a tractor starter solenoid is essential for ensuring smooth operations. By following the steps outlined in this guide, you can effectively troubleshoot and identify any issues with your tractor’s starter solenoid. Regular testing and maintenance will help to prevent unexpected breakdowns and keep your tractor running efficiently.